Unit of competency details

NWPTRT001 - Operate and control water treatment processes (Release 1)

Summary

Usage recommendation:

Superseded

Releases:

| 1 1 (this release) |

07/Dec/2015 |

Companion volumes:

Unit of competency

Assessment requirements

Training packages that include this unit

Qualifications that include this unit

Skill sets that include this unit

Classifications

Classification history

| ASCED Module/Unit of Competency Field of Education Identifier | 030907 | Water And Sanitary Engineering | 29/Apr/2016 | |

The content being displayed has been produced by a third party, while all attempts have been made to make this content as accessible as possible it cannot be guaranteed. If you are encountering issues following the content on this page please consider downloading the content in its original form

Unit of competency

Modification History

|

Release

|

Comments

|

|

1

|

This unit was released in NWP Water Training Package release 1.0 and meets the Standards for Training Packages.

- New unit, created drawing upon information from deleted units NWP260A, NWP261A and NWP345B

|

Application

This unit of competency describes the skills required to operate and control a water treatment plant, to report on water treatment plant system performance and process quality control. The ability to operate water treatment processes in urban and/or rural areas, in compliance with relevant water legislation and regulations and Australian Drinking Water Guidelines, is vital to performance.

This unit applies to those working as operational staff in water treatment plants with responsibility for the practical and safe operation of plant, equipment and processes.

The skills and knowledge described in this unit must be applied within the legislative, statutory, regulatory and policy environment in which they are carried out. Organisational policies and procedures must be consulted and adhered to.

Those undertaking this unit would work under supervision, while performing routine tasks, within a familiar context.

No licensing, legislative or certification requirements apply to unit at the time of publication.

Competency Field

Treatment

Elements and Performance Criteria

|

ELEMENTS

|

PERFORMANCE CRITERIA

|

|

Elements describe the essential outcomes

|

Performance criteria describe the performance needed to demonstrate achievement of the element. Where bold italicised text is used, further information is detailed in the range of conditions section.

|

|

1. Plan and prepare for work

|

1.1 Determine work requirements from job specifications and plans.

1.2 Select and check equipment to meet safety requirements of task and site.

1.3 Select, fit and use safety equipment including personal protective equipment.

|

|

2. Operate and control process

|

2.1 Carry out routine plant inspections according to the type of plant.

2.2 Identify and report process faults and the operational condition of the plant.

2.3 Collect samples and conduct standard tests.

2.4 Carry out basic adjustments to improve process performance.

|

|

3. Complete documentation

|

3.1 Collect, interpret, record and complete process data.

3.2 Identify data that falls outside normal parameters and report for further action.

|

Foundation Skills

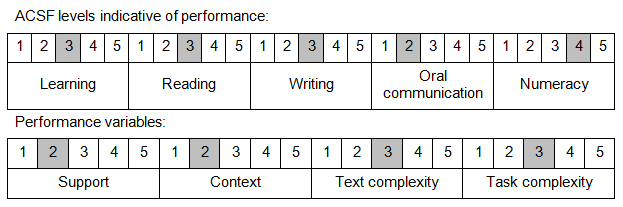

The foundation skills demands of this unit have been mapped for alignment with the Australian Core Skills Framework (ACSF). The following tables outline the performance levels indicated for successful attainment of the unit.

Further information on ACSF and the foundation skills underpinning this unit can be found in the Foundation Skills Guide on the GSA website.

Range of Conditions

|

Current processes include:

|

- chemical dosing

- coagulation

- pH adjustment

- iron manganese

- pre-screening

- clarification

- filtration

- DAF

- disinfection

- post-treatment

- fluoride

- ozone

- BAC

- stabilisation

|

Unit Mapping Information

No equivalent unit.

Links

Companion Volume implementation guides are found in VETNet - https://vetnet.gov.au/Pages/TrainingDocs.aspx?q=26336bc0-04e5-49d9-8c31-46c49b6a0037

Companion Volume implementation guides are found in VETNet - https://vetnet.gov.au/Pages/TrainingDocs.aspx?q=26336bc0-04e5-49d9-8c31-46c49b6a0037

Companion Volume implementation guides are found in VETNet - https://vetnet.gov.au/Pages/TrainingDocs.aspx?q=26336bc0-04e5-49d9-8c31-46c49b6a0037

Companion Volume implementation guides are found in VETNet - https://vetnet.gov.au/Pages/TrainingDocs.aspx?q=26336bc0-04e5-49d9-8c31-46c49b6a0037

Assessment requirements

Modification History

|

Release

|

Comments

|

|

1

|

These Assessment Requirements were released in NWP Water Training Package release 1.0 and meet the Standards for Training Packages.

|

Performance Evidence

Evidence required to demonstrate competence must satisfy all of the requirements of the elements and performance criteria. The candidate must be assessed operating at least two of the processes listed in the Range of Conditions, of which one must be from separation and one from disinfection. If not otherwise specified the candidate must demonstrate evidence of performance of the following on at least one occasion.

- conducting routine plant inspections

- interpreting safety data sheets (SDS)

- applying basic mathematical formulae

- completing logs

- preparing and applying chemical dosing including at least one of:

- pH adjustment

- coagulants

- polymers

- flocculants

- disinfectants

- fluoride

- interpreting plans, charts and instructions

Knowledge Evidence

Evidence required to demonstrate competence must satisfy all of the requirements of the elements and performance criteria. If not otherwise specified the depth of knowledge demonstrated must be appropriate to the job context of the candidate.

- water cycle

- sources of water

- demands and uses of water, both domestic and industrial

- physical, chemical and microbiological characteristics of water within the water treatment process

- reasons for water treatment

- types of treatment plants and processes

- major chemicals and equipment used

- water treatment plant hazards

- risk factors and potential hazards associated with the operation of water treatment processes

- physical, chemical and microbiological characteristics of water within the water treatment process

- chemical and biological principles that form the basis of water treatment

- types of components

- relevant technologies

- water quality principles

- relevant guidelines and standards

- risk management principles of water treatment (HACCP)

- basic knowledge of types of chemicals and water chemistry

Candidate should demonstrate basic knowledge of all processes listed in Range of Conditions.

Assessment Conditions

Competency should be assessed in an actual workplace or in a simulated environment, with access to equipment and infrastructure appropriate to the outcome. Competency should be demonstrated over time to ensure the candidate is assessed across a variety of situations.

Assessors must satisfy the NVR/AQTF mandatory competency requirements for assessors.

Links

Companion Volume implementation guides are found in VETNet - https://vetnet.gov.au/Pages/TrainingDocs.aspx?q=26336bc0-04e5-49d9-8c31-46c49b6a0037

Companion Volume implementation guides are found in VETNet - https://vetnet.gov.au/Pages/TrainingDocs.aspx?q=26336bc0-04e5-49d9-8c31-46c49b6a0037

Companion Volume implementation guides are found in VETNet - https://vetnet.gov.au/Pages/TrainingDocs.aspx?q=26336bc0-04e5-49d9-8c31-46c49b6a0037

Companion Volume implementation guides are found in VETNet - https://vetnet.gov.au/Pages/TrainingDocs.aspx?q=26336bc0-04e5-49d9-8c31-46c49b6a0037