Unit of competency details

NWPTRT015 - Operate and control coagulation and flocculation processes (Release 1)

Summary

Usage recommendation:

Superseded

Releases:

| 1 1 (this release) |

07/Dec/2015 |

Companion volumes:

Unit of competency

Assessment requirements

Training packages that include this unit

Qualifications that include this unit

Accredited courses that have this unit in the completion mapping

Classifications

Classification history

| ASCED Module/Unit of Competency Field of Education Identifier | 030717 | Plant And Machine Operations | 29/Apr/2016 | |

The content being displayed has been produced by a third party, while all attempts have been made to make this content as accessible as possible it cannot be guaranteed. If you are encountering issues following the content on this page please consider downloading the content in its original form

Unit of competency

Modification History

|

Release

|

Comments

|

|

1

|

This unit was released in NWP Water Training Package release 1.0 and meets the Standards for Training Packages.

This unit supersedes and is equivalent to NWP347B Monitor, operate and control coagulation and flocculation processes.

- Unit code updated

- Content and formatting updated to comply with the new standards

- All PC transitioned from passive to active voice

- Unit title changed to better reflect unit outcomes

- Two new PC added to Element 1

|

Application

This unit of competency describes the skills required to monitor, operate and control coagulation and flocculation processes; and to measure and report on system performance and quality control. The ability to identify faults, determine and apply technical adjustments and conduct chemical dosing procedures.

This unit applies to those working as operational staff with a specific responsibility for coagulation and flocculation processes in water and wastewater plants.

The skills and knowledge described in this unit must be applied within the legislative, regulatory, statutory and policy environment in which they are carried out. Organisational policies and procedures must be consulted and adhered to, particularly those relating to safety, water testing, chemical dosing, handling and storage of hazardous substances and dangerous goods.

Those undertaking this unit would work under supervision, while performing routine tasks, within a familiar context.

No licensing, legislative or certification requirements apply to unit at the time of publication.

Competency Field

Treatment

Elements and Performance Criteria

|

ELEMENTS

|

PERFORMANCE CRITERIA

|

|

Elements describe the essential outcomes

|

Performance criteria describe the performance needed to demonstrate achievement of the element. Where bold italicised text is used, further information is detailed in the range of conditions section.

|

|

1. Monitor coagulation and flocculation processes

|

1.1 Monitor test results and processes to ensure compliance with the parameters of the operation.

1.2 Identify and report process faults and the operational condition of plant.

1.3 Collect and test samples.

1.4 Conduct jar tests and determine dosages.

|

|

2. Control chemical use

|

2.1 Use, handle and store chemicals.

2.2 Determine and apply chemical dosing according to plant processes based on jar testing.

2.3 Maintain chemical supply and usage records.

|

|

3. Operate and control coagulation and flocculation processes

|

3.1 Carry out routine plant inspections.

3.2 Collect process samples and conduct standard tests such as jar testing.

3.3 Carry out system adjustments and process calculations to improve system performance whenever water quality changes or process performance deteriorates.

|

|

4. Complete documentation

|

4.1 Compile reports from plant and system data.

4.2 Report observations outside defined parameters for further action.

|

Foundation Skills

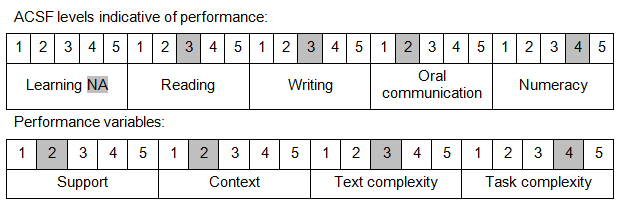

The foundation skills demands of this unit have been mapped for alignment with the Australian Core Skills Framework (ACSF). The following tables outline the performance levels indicated for successful attainment of the unit.

Further information on ACSF and the foundation skills underpinning this unit can be found in the Foundation Skills Guide on the GSA website.

Unit Mapping Information

This unit supersedes and is equivalent to NWP347B Monitor, operate and control coagulation and flocculation processes.

Links

Companion Volume implementation guides are found in VETNet - https://vetnet.gov.au/Pages/TrainingDocs.aspx?q=26336bc0-04e5-49d9-8c31-46c49b6a0037

Companion Volume implementation guides are found in VETNet - https://vetnet.gov.au/Pages/TrainingDocs.aspx?q=26336bc0-04e5-49d9-8c31-46c49b6a0037

Companion Volume implementation guides are found in VETNet - https://vetnet.gov.au/Pages/TrainingDocs.aspx?q=26336bc0-04e5-49d9-8c31-46c49b6a0037

Companion Volume implementation guides are found in VETNet - https://vetnet.gov.au/Pages/TrainingDocs.aspx?q=26336bc0-04e5-49d9-8c31-46c49b6a0037

Assessment requirements

Modification History

|

Release

|

Comments

|

|

1

|

These Assessment Requirements were released in NWP Water Training Package release 1.0 and meet the Standards for Training Packages.

- Assessment Requirements created drawing upon specified assessment information from superseded unit

|

Performance Evidence

Evidence required to demonstrate competence must satisfy all of the requirements of the elements and performance criteria. If not otherwise specified the candidate must demonstrate evidence of performance of the following on at least one occasion.

- taking samples and performing tests including at least one of:

- flocculation growth and size

- flocculation time

- mixing time

- mixing energy

- pH

- colour

- turbidity

- routine jar tests and associated timings

- residual aluminium or iron

- alkalinity

- drop tests

- dosage feed rate review and checks

- producing logs and reports

- preparing testing solutions and solutions strengths

- performing process calculations including at least one of:

- preparation of dosing solutions

- jar test dosages

- dry and liquid chemical feed rates

- mixing intensity

- preparing and applying chemical dosing

- applying optimised jar test results in the process

- conducting routine plant inspections

- identifying and reporting system faults

- making basic system adjustments including at least one of:

- pH correction

- chemical dosing

- completing required documentation including at least one of:

- routine plant inspection and safety checks

- water quality sampling and test results

- routine maintenance reports

- chemical dosing calculations

- process set point changes

- water quality and safety incident reports

Knowledge Evidence

Evidence required to demonstrate competence must satisfy all of the requirements of the elements and performance criteria. If not otherwise specified the depth of knowledge demonstrated must be appropriate to the job context of the candidate.

- process layout

- process flash mix

- flocculation process

- chemicals used i.e. polymers, coagulants, flocculants and pH correction

- features and components of coagulation and flocculation systems

- process operations including:

- chemical addition

- flash mixing

- flocculation

- chemicals used for coagulation and flocculation

- chemical dosing processes

- risk factors and potential hazards related to coagulation and flocculation systems including:

- aluminium and iron based coagulants

- synthetic organic polymers

- pH adjusting chemicals such as lime, soda ash, caustic soda

- risk control requirements including safety equipment and safety data sheets (SDS)

- operation of pumping and valving systems

- control and communications systems

- water testing procedures

- effects of weather and conditions on operation of site or plant

- procedures for storing and handling dangerous goods and chemicals

- understanding risk management principles of ADWG and AGWR

- jar testing dosage and calculations

Assessment Conditions

Competency should be assessed in an actual workplace or in a simulated environment, with access to equipment and infrastructure appropriate to the outcome. Competency should be demonstrated over time to ensure the candidate is assessed across a variety of situations.

Some components of this unit require assessment in a workplace environment therefore the unit is not suitable for fully external or electronic based assessment.

Consideration must be given to holistic assessment for this unit. Refer to advice in the companion volumes.

Assessors must satisfy the NVR/AQTF mandatory competency requirements for assessors.

Links

Companion Volume implementation guides are found in VETNet - https://vetnet.gov.au/Pages/TrainingDocs.aspx?q=26336bc0-04e5-49d9-8c31-46c49b6a0037

Companion Volume implementation guides are found in VETNet - https://vetnet.gov.au/Pages/TrainingDocs.aspx?q=26336bc0-04e5-49d9-8c31-46c49b6a0037

Companion Volume implementation guides are found in VETNet - https://vetnet.gov.au/Pages/TrainingDocs.aspx?q=26336bc0-04e5-49d9-8c31-46c49b6a0037

Companion Volume implementation guides are found in VETNet - https://vetnet.gov.au/Pages/TrainingDocs.aspx?q=26336bc0-04e5-49d9-8c31-46c49b6a0037